PRODUCTS

AI-equipped 3D Tracking and Visual Inspection System KITOV

Leave these problems to KITOV!

- ■ Fixed camera cannot capture inspection points

- ■ Texture and material properties are deceptive and undetectable

- ■ Cannot keep up with specification/process changes and high-mix low-volume production

Visual inspection vs. conventional fixed camera vs. KITOV

| Visual inspection | Conventional fixed camera | |

|---|---|---|

| +POINT | ■ Detects difficult defects in a short time ■ Experience improves inspection skills |

■ Capable of inspecting at a constant quality and speed in the process of mass production of a single product |

| -POINT | ■ Inspection quality varies depending on the physical condition of the inspector ■ Variations in inspection quality due to individual differences ■ Difficult to hire ■ It takes time to acquire skills |

■ Not compatible with full product inspections ■ Difficult to handle various shapes and materials ■ Not suitable for small-lot, high-mix production lines |

What KITOV can do!

Visual inspection systems that have faced a variety of challenges up to now are KITOV solves the problem!

-

Streamlining inspection setup operations

-

Rule-based and deep learning combined highly accurate detection

-

Pendant-less robot teaching with auto-scan

-

Maximize imaging capability with robotic arms and multiple lighting

-

Collect more accurate data with 3D inspection

-

Flexibility through superior AI

-

Additional inspection functions can be added

-

Supports small-lot production of a wide variety of products

-

Traceability with image data

Changing Appearance Inspection! KITOV Quality

Strength of KITOV

-

Hybrid image processing

・Achieving image processing that combines the best of rule-based and deep learning techniques

-

User Interface Easy to Operate

・Robot teaching from PC without pendant

・Check search results on touch panel -

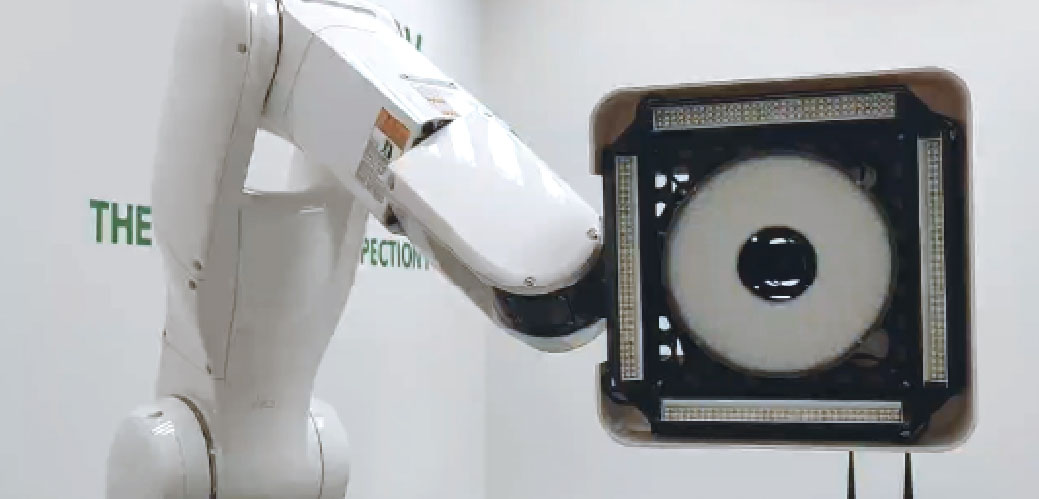

Advanced shooting ability

・Robot arm and multiple lights

-

Compatible with various defects to be inspected

・Flexible features and high versatility

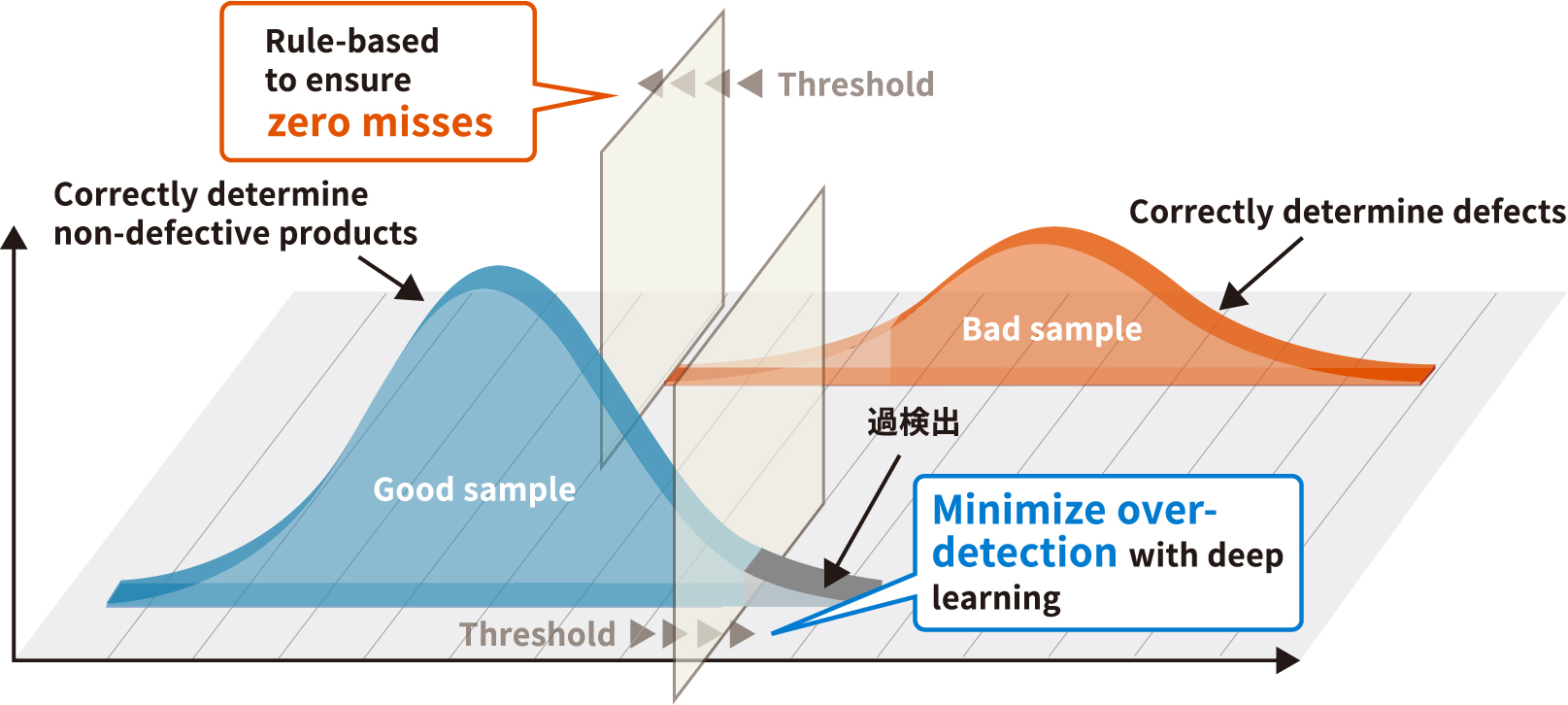

Hybrid Image Processing

Unique image processing quickly detects defects

Hybrid image processing that combines rule-based and deep learning reduces over-detection

Advanced imaging capabilities

-

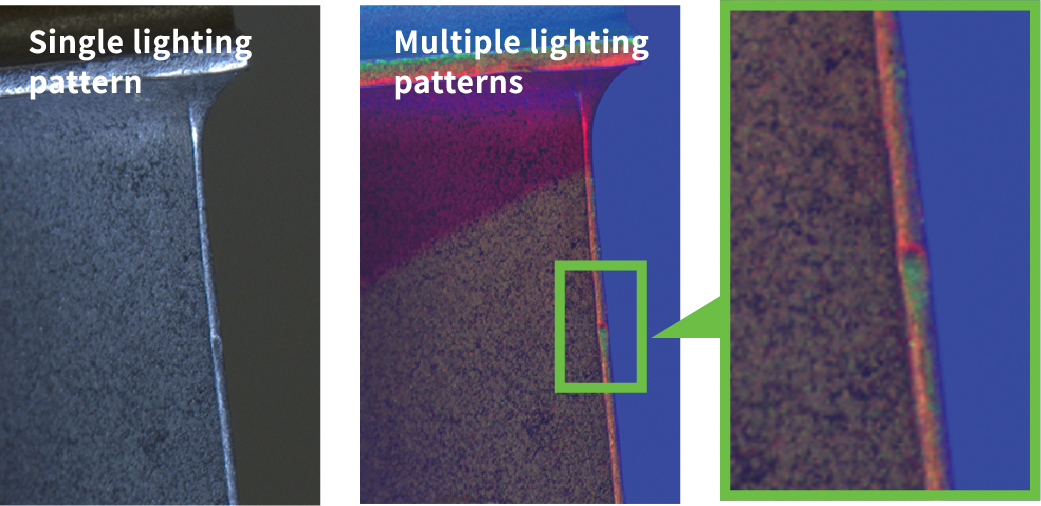

■ Smart optical head with 5 light sources

-

■ Efficient 3D tracking by robotic arm

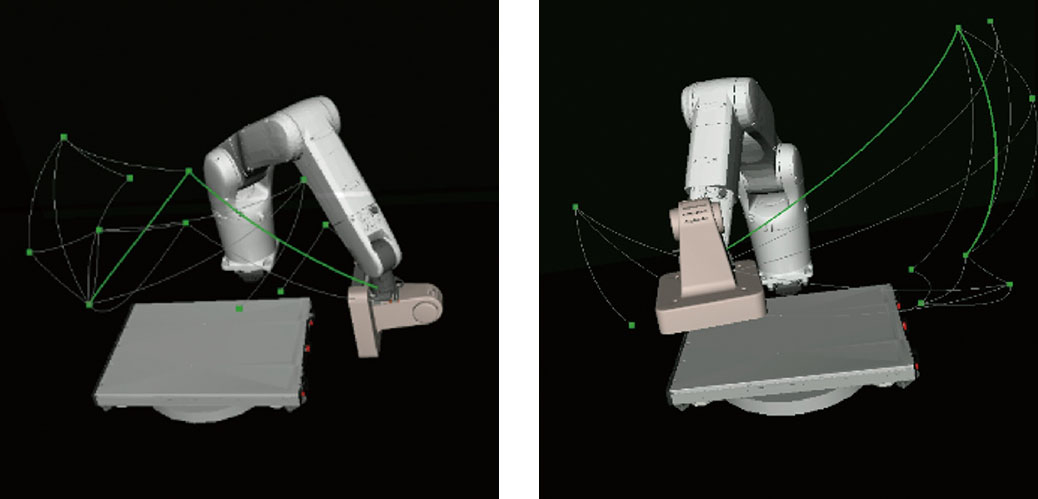

Easy teaching to set optimal shooting and checkpoints

-

■ Multiple lighting patterns for precise shots

Multiple lighting patterns are used to clarify and detect abnormalities

-

■ Automatic optimization of captured images

Automatic selection of the most efficient shooting route

Easy-to-operate user interface

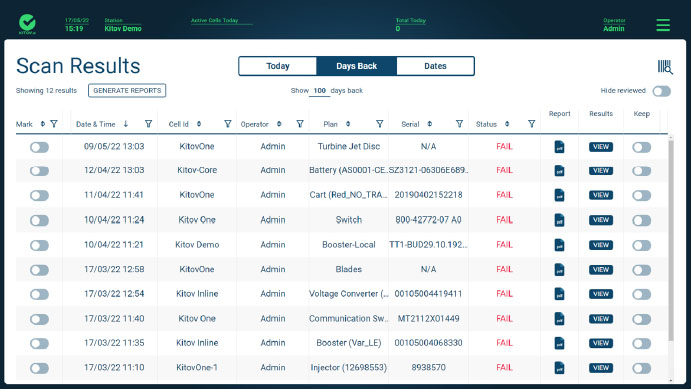

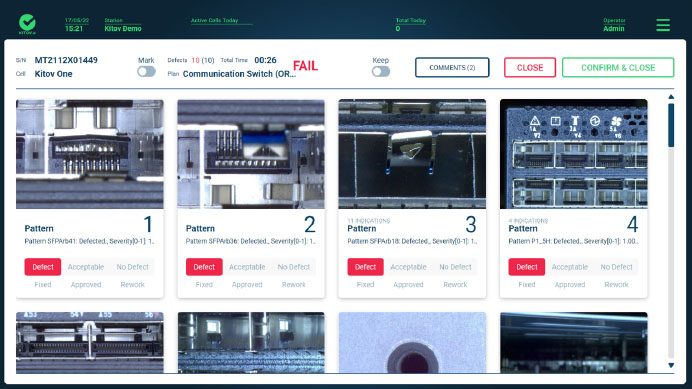

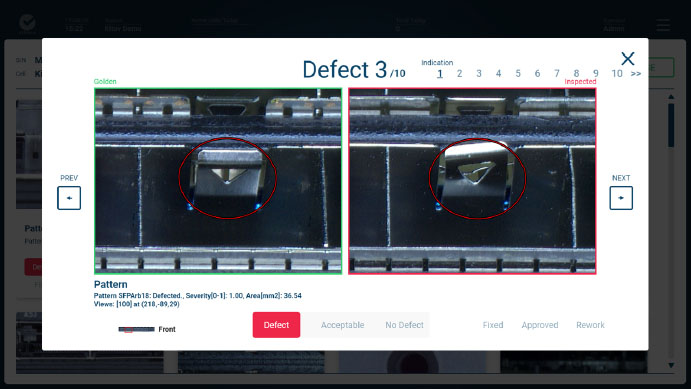

【Easy-to-understand settings and results display】

-

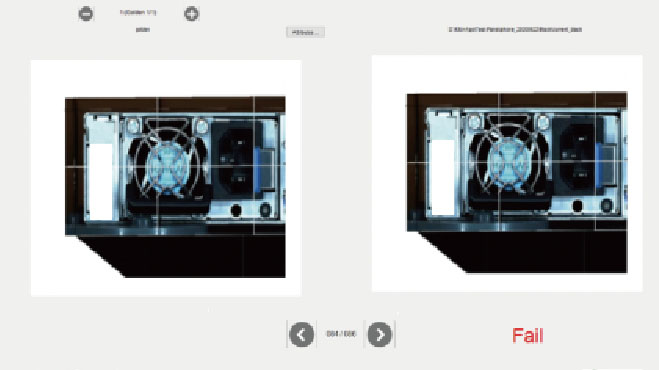

List of Inspection Results

-

Defective area thumbnail

-

Detailed defect location indication

【Operation Flow】

Acquire product information by bending in or 3D scanning,

and set up the necessary information on the screen. No special knowledge is required.

-

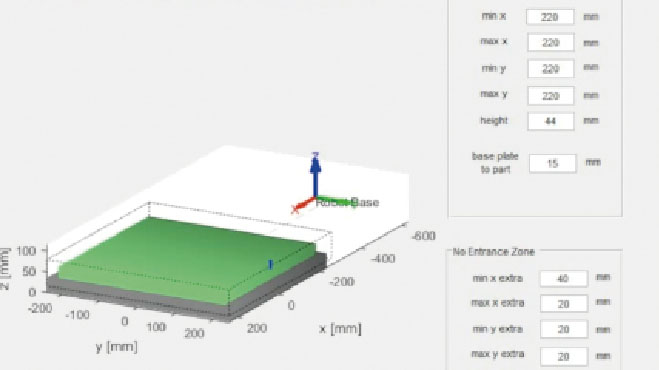

STEP1Import 3D CAD

Enter the size of the product to be inspected in the software

-

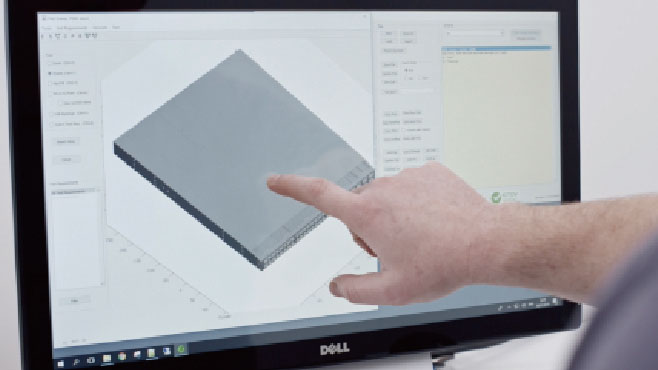

STEP2Data capture by 3D scanning

3D scanning of good products and capturing the basic product data

-

STEP3Creating 3D Models

Create a 3D image model of the good based on the imported data

-

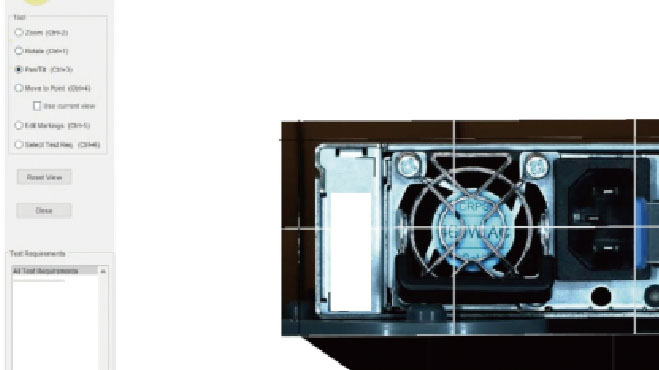

STEP4Set inspection points and items

Specify on software the points you want to inspect

-

STEP5Set thresholds

Set image processing parameters to detect defects

-

STEP6Start inspection

Start automatic inspection

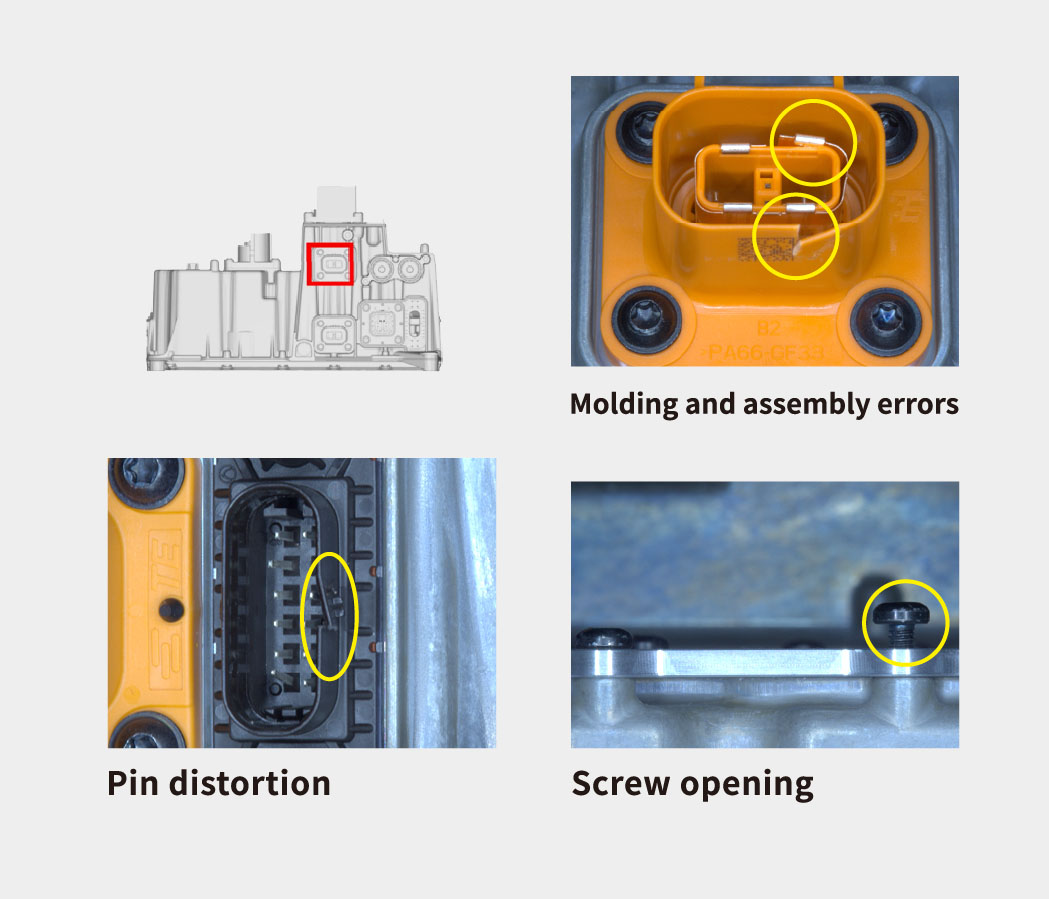

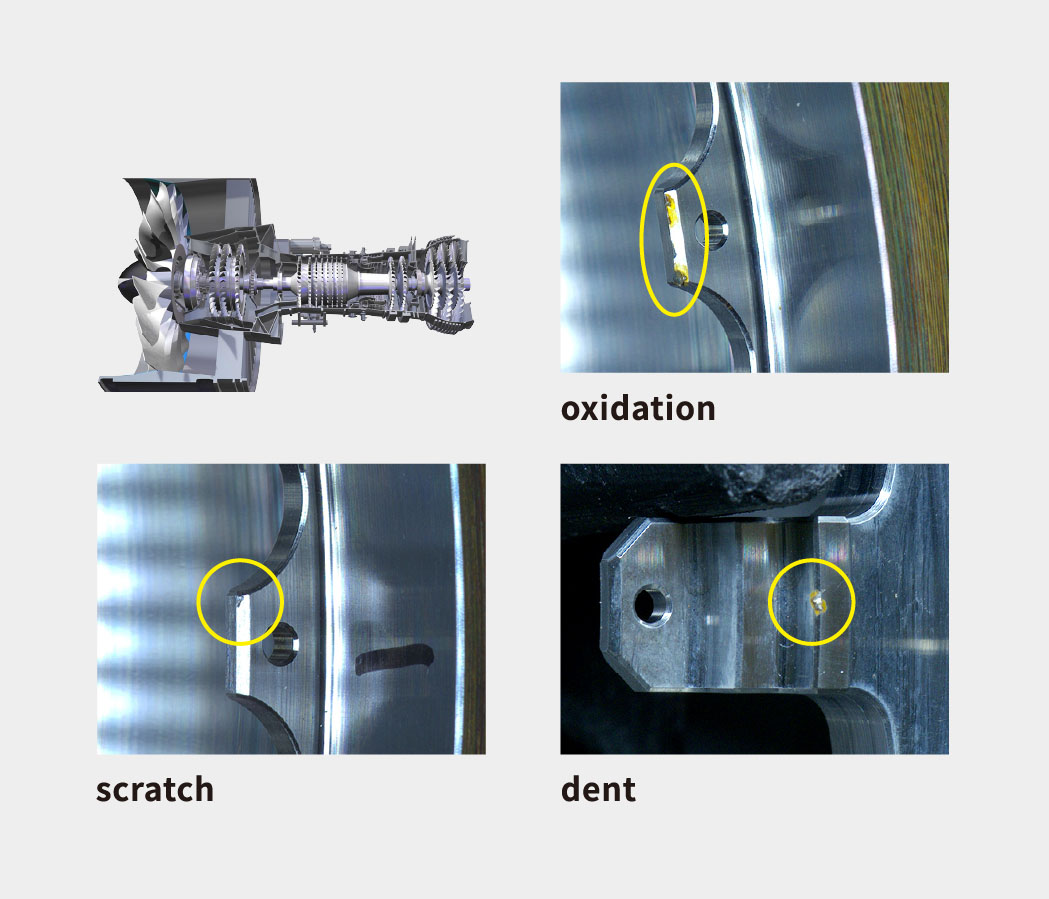

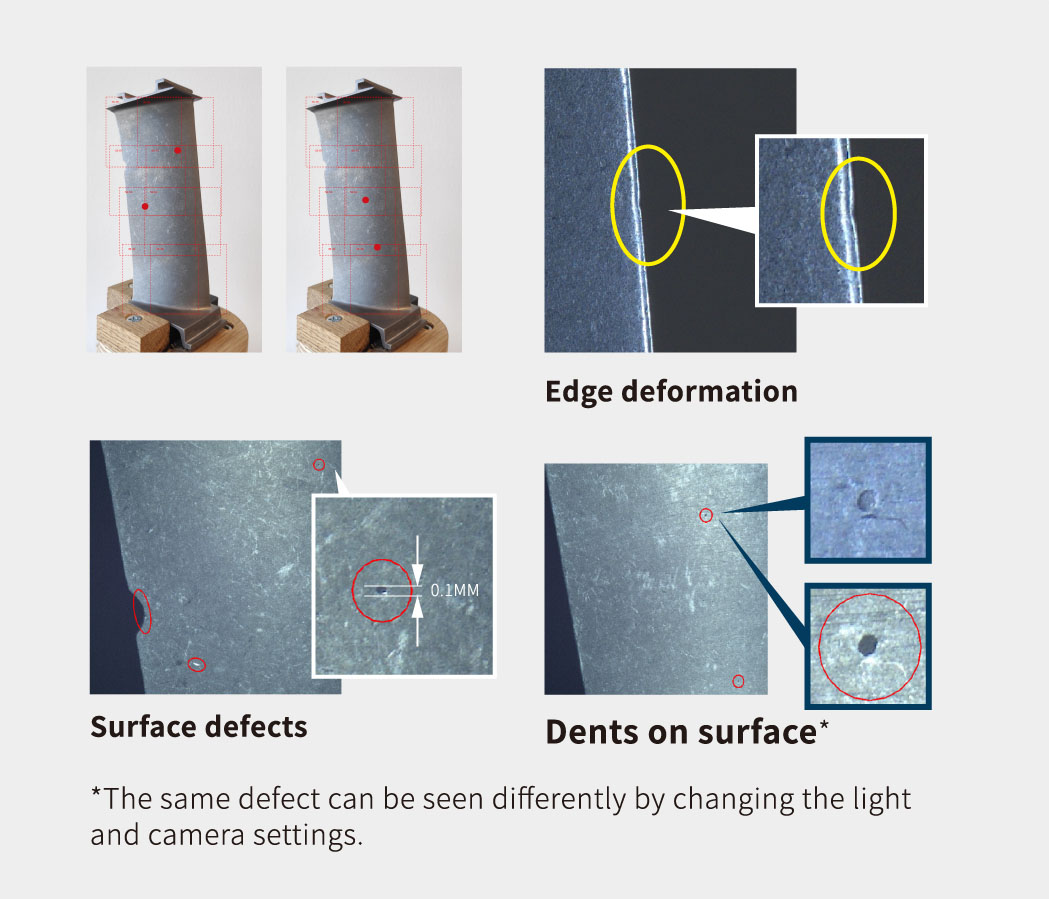

Support for various defects to be inspected

- ■ Flexible solutions for various products

- ■ Improved inspection efficiency for a variety of industrial applications

- ■ Multiple patterns available

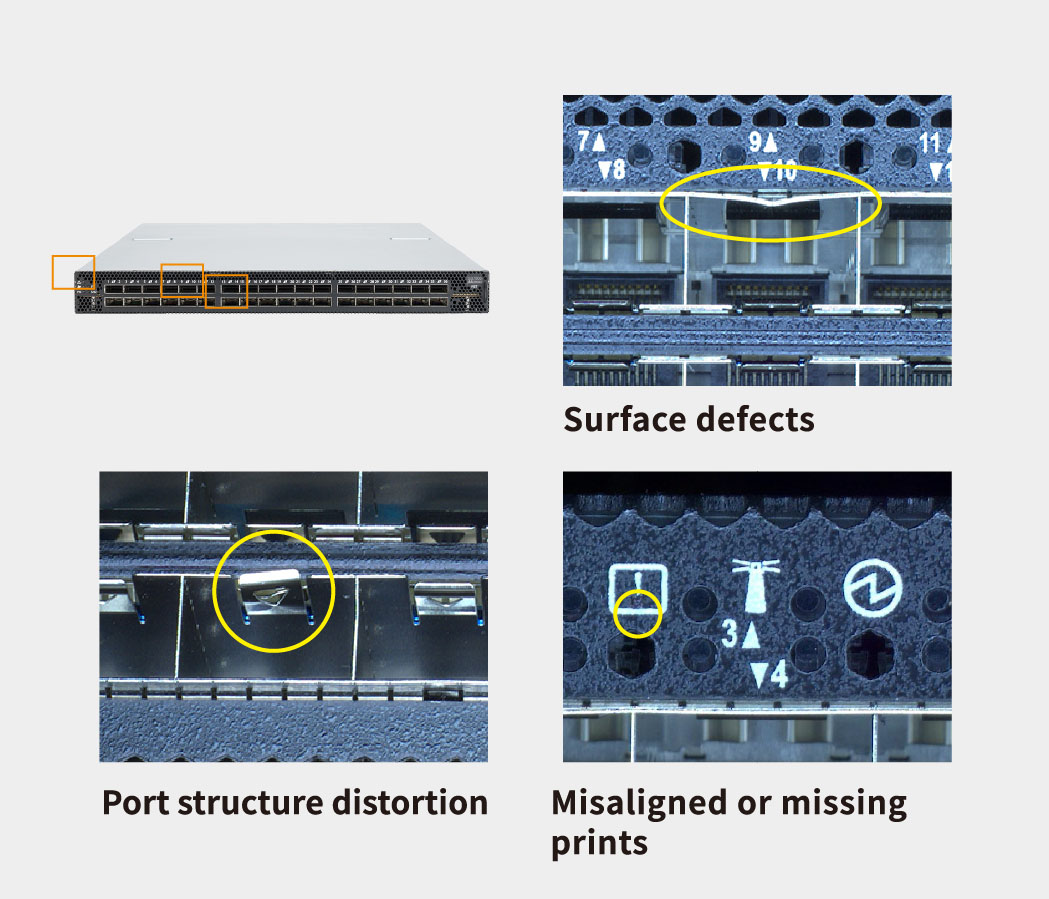

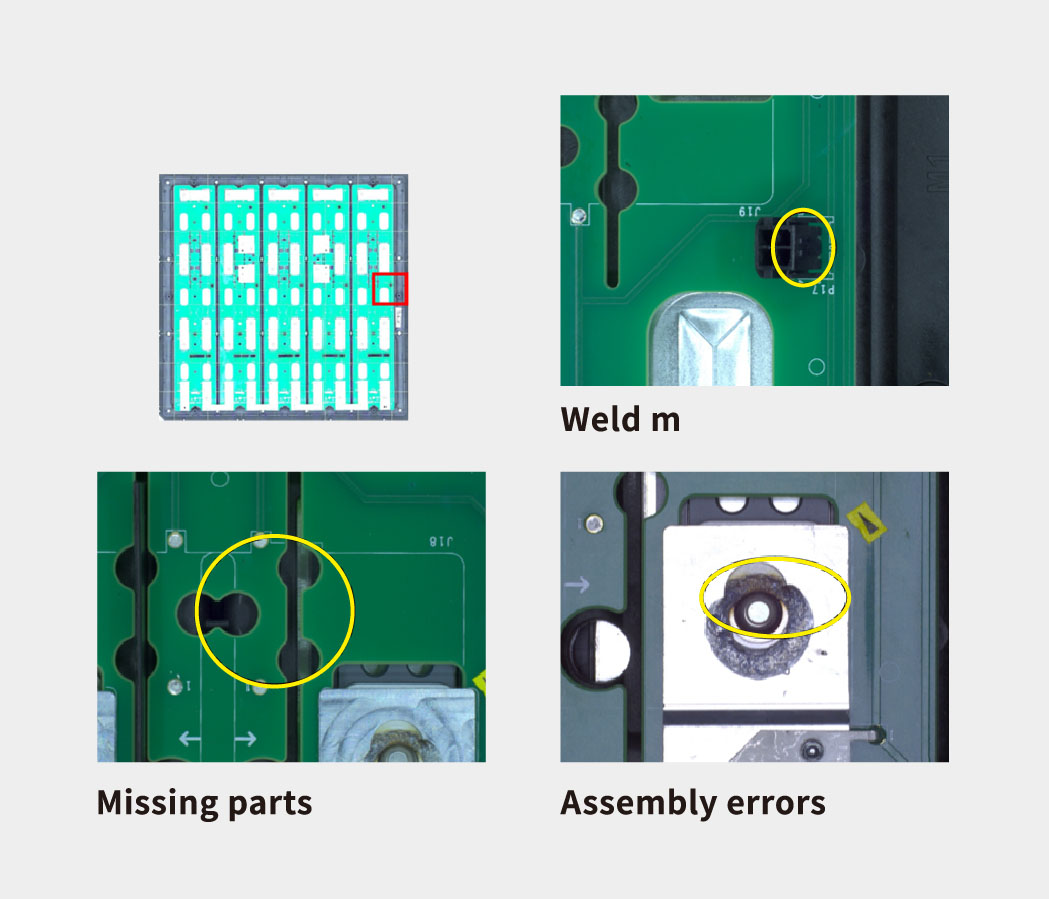

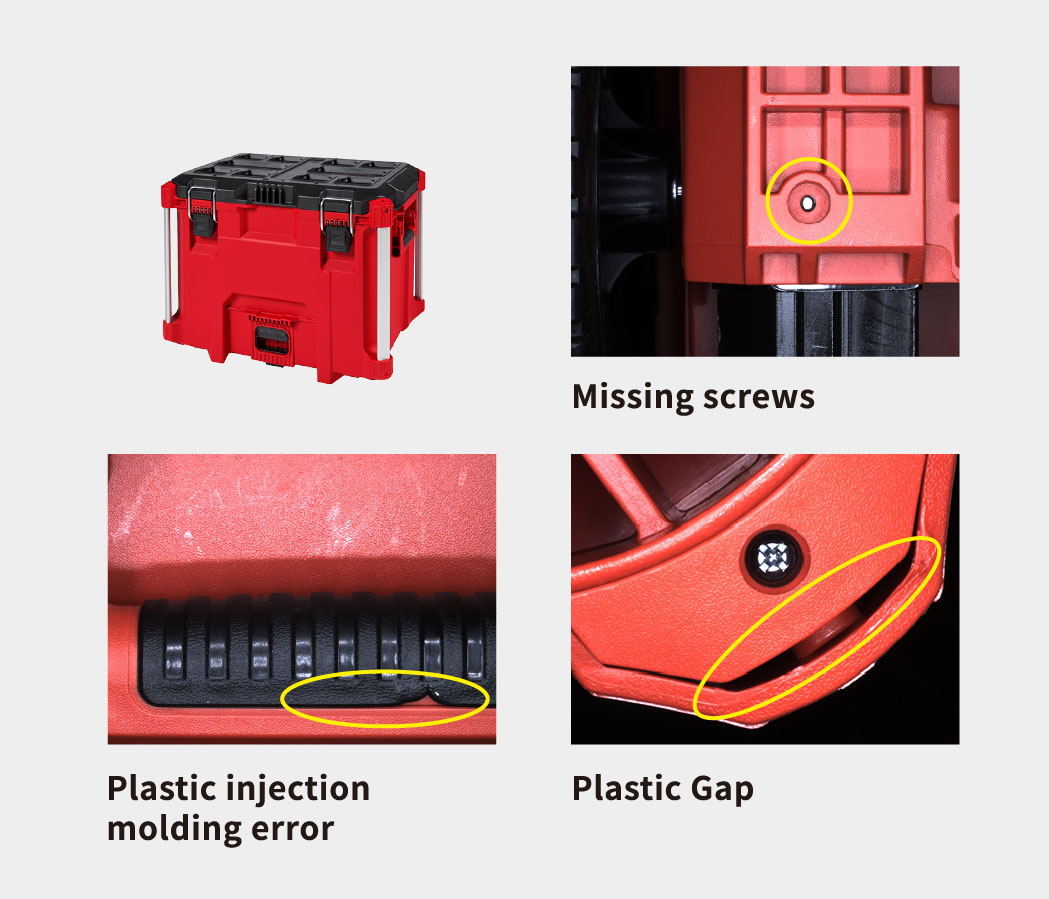

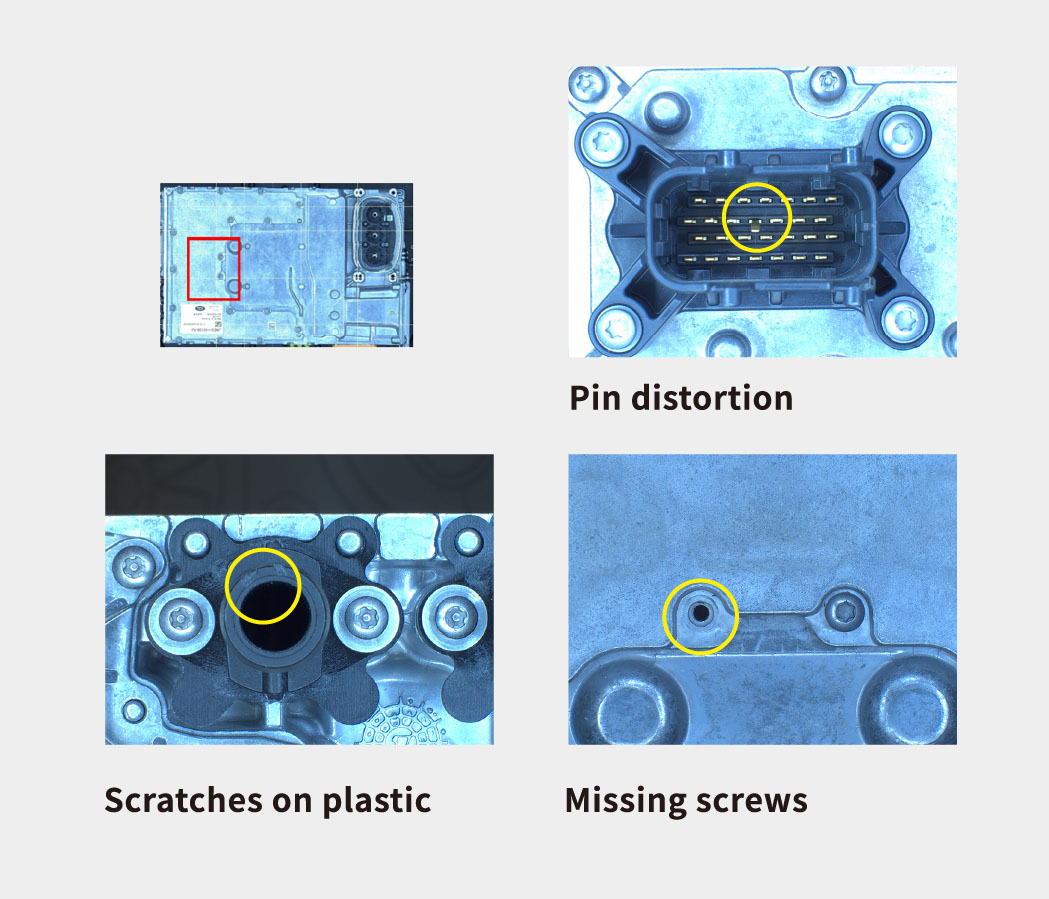

【Defect detection examples】

-

■ Server

-

■ Base

-

■ Toolbox

-

■ EV Power Booster

-

■ EC Power Booster

-

■ Jet engine

-

■ Blade

Flow of Introduction

-

1. Products

Learn about KITOV, its products and technologies, and case studies.

-

2. Consultation and Hearing

Hearing of inspection requirements and proposal of contents and direction of test evaluation.

-

3. Trial Evaluation

Receive samples of good and defective products and evaluate whether they can be detected or not according to your requirements.

-

4. n-increase evaluation (Extended number of verifications)

If the test evaluation is "good", we will increase the number of inspections, collect data, and confirm accuracy (this service is available for a fee).

-

5. Ordering and delivery

Delivered after order placement. Please consult us for operation support, maintenance, etc.

System configuration

KITOV

KITOV (with swivel table)

Specification

| External shape | W856 mm ×D1157 mm ×H1785 mm (with rotating table-Reference value) |

|---|---|

| Mass | 350 kg (with rotating table-Reference value) |

| Power Supply | Number of phases Single-phase Voltage AC200-15% ~AC240+10% V |

| Detectable Defect Size | 0.1mm and the above |

| Target Work Size | Diameter 800mm × Within height 400mm ※ (with rotating table-Reference value) |

| Target work mass | Within 40kg (including the weight of the workpiece fixing jig) *When using a rotary table |

| CMOS camera | 5 million pixels, color |

| Angle of view | 85mm × 71mm (negotiable) |

| Ring type LED lighting | 1 white light |

| Bar type LED lighting | 4 types of white light |

About KITOV.ai

Founded in 2014, KITOV.AI has been a pioneer in visual inspection, providing fully automated visual inspection solutions to a wide range of markets, helping to reduce costs and improve quality and efficiency.

Our goal is to develop innovative solutions that can be operated intuitively by anyone, utilizing cutting-edge technologies such as deep learning, advanced robotics, and big data analysis.