The power semiconductor market is expanding as the world strives to build a decarbonated society. We introduced a Si-IGBT laser annealing equipment in 2004, and SiC laser annealing equipment in 2014, shipping over 100 units thus far.

SOLUTION

Laser Annealing

Selecting the laser source for SiC laser annealing equipment, an essential technology for manufacturing power semiconductors

Customers’ issues

- Selecting a laser source in consideration of the need to use a thinner and more productive wafer

- Considering heat damage from a laser source (Green/UV) as a result of making SiC power devices thinner

- Balancing the control of heat damage and productivity in SiC power devices

What has been resolved and what can be resolved

Pre-considering irradiation conditions through simulation.

Conducting irradiation tests to verify simulation results and suggest optimum conditions.

Focuses in selecting a light source for SiC laser annealing equipment.

Laser annealing, an essential part of manufacturing next-generation power semiconductor, SiC

Two models available: SWA-20US and SWA-90GD

Attention is mounting in recent years on SiC as next-generation power semiconductor. Compared to Si, SiC has triple the band gap and ten times the dielectric breakdown, demonstrating its superiority in device performance. However, it is more expensive in terms of material and process costs, and has generally been used for electric railways and power transmission applications. At the same time, the recent trend to tighten exhaust gas regulations in many countries has spread the use of SiC in consumer products including electric vehicles (EV, PHEV, HEV) and charging stations for EVs. Against the background lies a series of corporate efforts to make SiC fibers’ diameter larger, improve productivity and streamline manufacturing processes, thus bringing its costs to the extent that it can meet requirements for consumer products.

Our lineup of SiC laser annealing equipment consists of SWA-20US, a model that uses a third harmonic laser (UV) as the laser source, and SWA-90GD, a model that uses second harmonic laser (Green).

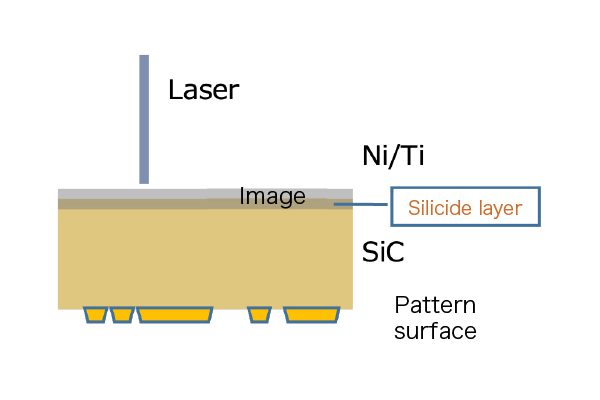

Application: Silicide annealing

SiC annealing is used to produce a silicide (alloy) layer on backside electrode.

*Reference: In Si-IGBT, this technology is widely used for activating impurities injected on the backside.

Focuses in selecting the laser source

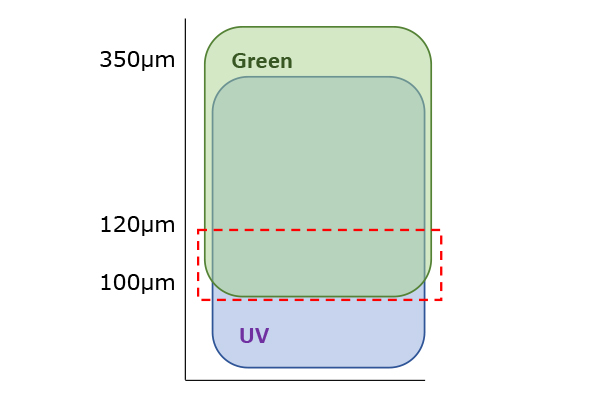

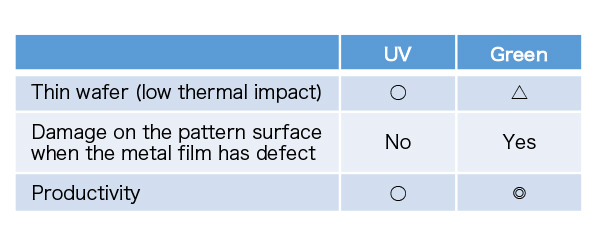

①Thickness of a SIC device

Compared to UV laser, green laser has a low absorption rate against metal, and therefore has higher fluence for irradiation in annealing conditions. Accordingly, there tends to be thermal damage on devices thinner than 100~120μm in general.

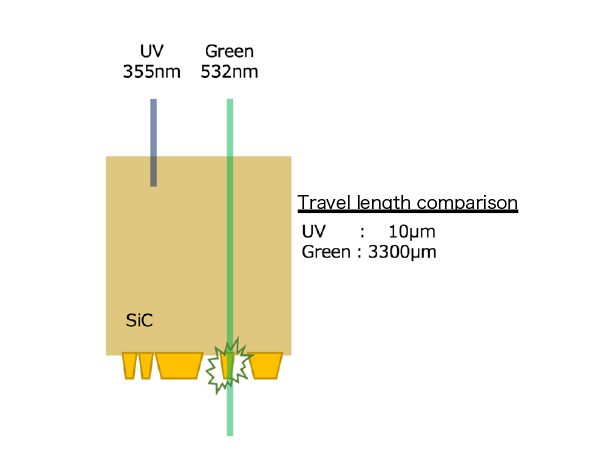

② Laser travel length for SiC

When irradiating a SiC wafer, laser has different travel lengths, depending on its wavelength. Green laser transmits to the frontside surface (pattern surface). This poses the risk of destroying a pattern when the metal film (Ni/Ti) has a defect.

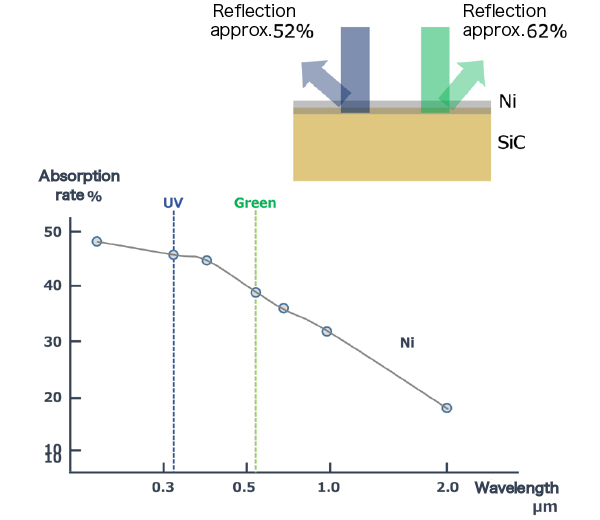

③ Absorption rate against the metal film (Ni)

Laser’s absorption rate against the metal film varies depending on the wavelength of the laser.

If the identical annealing result is required, a lower reflectivity (= higher absorption rate) requires less energy. Higher energy input, on the other hand, could cause a thermal damage on the device.

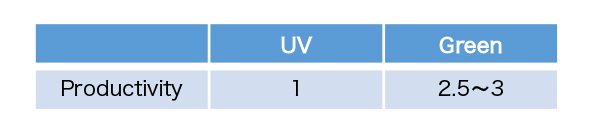

④ Productivity

Irradiation conditions vary depending on device structure and metal’s film-forming conditions. Generally speaking, green laser’s productivity is 2.5 – 3 times higher than UV laser.

Selecting the laser source for SiC laser annealing equipment

The laser source must be selected carefully according to the applicable device structure. We carry out simulation and testing to suggest the optimum annealing equipment based on the results. Please do not hesitate to contact us.

Click here for any queries on laser annealing.

Criteria in recommending a light source

- Equipment featuring UV laser for customers who are considering thinner devices

- Equipment featuring green laser for customers who prioritize productivity

Download a PDF about the Product brochure (laser annealing)

Download